“The Best Mining Equipment for Philippines Nickel Ore You Must Know“

What type of Philippines nickel mines belongs to?

Since Indonesia banned the exportation of nickel ore at the beginning of 2020, the Philippines has become a major supplier of nickel exporters.

The Philippines is the main producing area of lateritic nickel ore. The lateritic nickel ore has a complex composition divided into two types: limonite and silicon-magnesium nickel. It is accompanied by only a small amount of cobalt but without sulfur and calorific value, and is easy to mine in the open pit.

How to process Philippines nickel ore step by step?

Generally, like other ore beneficiation plants, laterite nickel ore processing needs several stages includes ore washing, crushing and screening, milling by ball mill, magnetic and froth flotation separating, and drying, and melting. The distribution of useful mineral nickel varies with the nature of the ore. Most useful minerals are rich in fine-grained grades, and you can learn that from Philippines BNML limonite with +50mm whose nickel grade is as high as 2.89%.

Stage one: washing nickel ore with fine and coarse material screw washer (a mining equipment)

Laterite nickel ore mostly exists in sapropelic deposits, and the content of laterite nickel increases with depth. Raw nickel ore is accompanied by clay and impurities always. The washing ore process can remove clay and impurities before crushing and beneficiation operations; which improves operating efficiency and helps to obtain high-grade nickel concentrate.

The ore washing equipment used in laterite ore mainly is a coarse and fine material screw washer. It can help you realize wash, classify and dewater lateritic nickel ore with -10mm or 3/8″ at one time. Compared with other ore washing machines; screw washers can retain more fine-sized products because of the unique design of sand recovery units; which greatly increases washing efficiency.

Stage two: crushing ore with optimal crushing mining equipment-cone crushers

The crushing process is necessary because when raw laterite nickel ore is excavated. It is often accompanied by columnar rocks with incomplete weathering and with large sizes. After crushing the huge block of nickel ore. Furthermore, it will be reduce to a small size; which ideally avoids screen mesh blocking.

A Cone crusher is the best machine to crush nickel ore. The lamination crushing principle makes the particle shape of the product even and excellent. In the process; a primary cone crusher can reduce the material size to -5 inches; then a short head cone crusher makes a further reduction to -1/2″ in size. Various types of crushing chambers perform high adaptability. Furthermore, the most outstanding feature is that its large head displacement; it allows a greater volume of material flow at every circle.

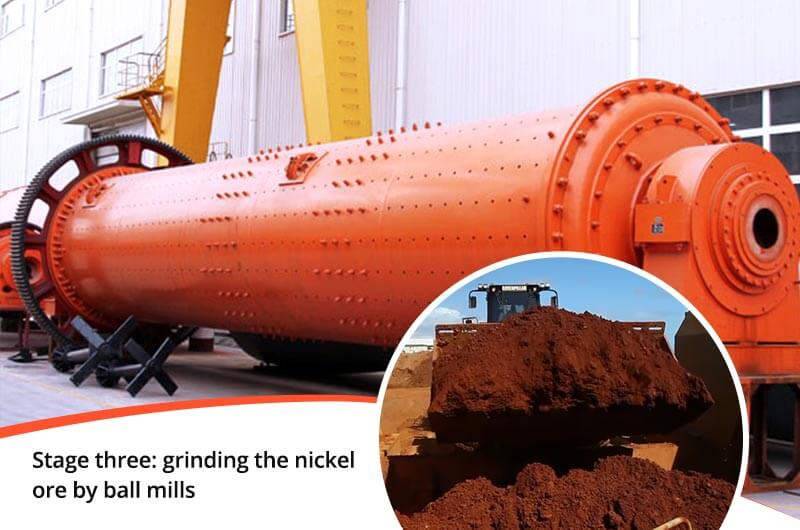

Stage three: grinding the nickel ore by ball mills

After being crushed by cone crushers, the nickel ore is then ground to -100 mesh in ball mills.

For wet or dry grinding ores and other raw materials use a ball mill; it can give a controlled final grind and produce flotation feed of a uniform size. It operated in a closed circuit with a particle-size measurement device and size-control cyclones, which can send correct-size material onto flotation.

Stage four: Wet magnetic separation and froth flotation

Wet magnetic separation is applied to get separated pyrrhotite. After that process; the pyrrhotite with -100 does not meet the requirements of froth flotation; which means that it should be reduce to -200 mesh in a ball mill. Moreover, classifications can be accomplish with screens and cyclones.

The next step is to send -200 mesh pyrrhotite to froth flotation equipment which can produce 3% nickel concentrate. But that is not the end; the left nonmagnetic ore should be sent to a series of; rougher, cleaner flotation cells, and from that, you can get around 31% copper concentrate. And the end; the tailings can be also used to recover the nickel by being sent to another flotation cell, thus the concentrate is combined with the 3% nickel concentrate to produce a 12% nickel concentrate.

Stage five: Rotary kiln (a mining equipment) – electric furnace reduction process

Drying by the rotary dryer and rotary kiln. Philippines nickel ore contains a large amount of moisture, the drying process is important and necessary. A rotary dryer is typically used to remove free moisture from the crushed nickel ore and once nickel ore has been dried, it is processed in a rotary kiln to remove chemically bound moisture and the oxide component of the ore. This process is pre-reduction. In order to avoid the formation of olivine above 800°C, the final plan is to control it at 770°C in the rotary kiln.

Reduction Smelting. After being process by the rotary kiln. Nickel is reduce and smelted further in an electric furnace. If you want to increase the grade of crude nickel-iron in the electric furnace to 35%, you can adopt the technology which cancels the blending of limestone flux. But you must focus on characteristics of laterite ore, the physicochemical reaction in the furnace, and other economic indicators.

When finishing the smelting step, the material would be fed into the rotary cooler at the end of the cylinder and cooled directly. By showering the material through a cool air stream or by spraying water onto the external surface of the cylinder. The final nickel product is then discharge at the other end.

The development of nickel laterite mines needs to consider the differences in nickel ore types, cobalt content, as well as the local supply of fuel, water, electricity, and chemical reagents.

For more info, visit this link page.

Source(s): https://www.ftmmachinery.com/